As a farm kid, I grew up with a smokehouse right outside the house in the front yard. It was a small brick structure without any door. My parents called it a smokehouse, but it was never used to smoke anything. The sole purpose of the “smokehouse” was to burn things…garbage, boxes, etc. Eventually they removed the smokehouse from the front yard to construct a fence.

Jesse started talking about building a smokehouse soon after we bought the farm. He finally turned his vision into a reality last summer. After a lot of research and sketches, he came up with a design.

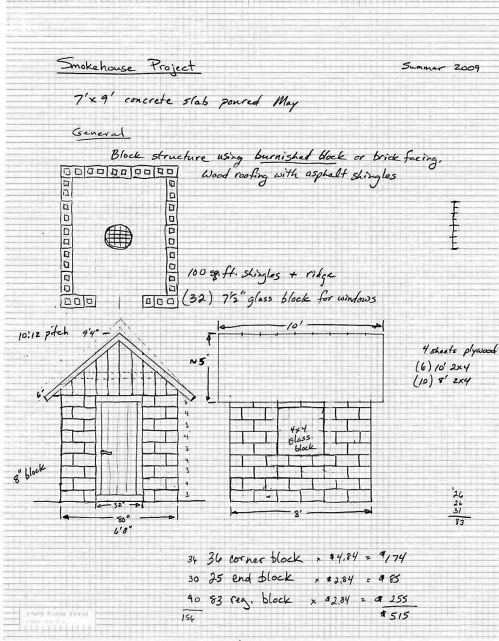

Smokehouse Design Sketch

Jesse already had a barrel smoker for hot-smoking or cook-smoking, but what he really wanted was a cold-smoker to be able to smoke pork sausage in the tradition that his grandfather used to do on the farm. There are also several other cold smoke products that are absolutely delicious: salmon, hams, cheese, nuts, and various sausages.

Cold-Smoking

The art of cold-smoking is to keep the meat or fish below 70 degrees F to inhibit bacteria growth and to not cook the meat product. For instance, if you would like smoked venison sausage, but don’t want to eat the complete deer all at once (who would….?), then cold-smoking will impart the desired smoke flavor and will also retain the fat inside the sausage so that it doesn’t become dry and hard. Toss cold-smoked venison sausage into the freezer until you are ready to cook it for another tasty meal.

Another example that we have become very fond of is cold-smoking 5 to 10 racks of baby back pork ribs, wrapping them in freezer paper and tossing them into the freezer. Take them out of the freezer later and bake them in the oven for a couple of hours and you have some of the best ribs ever!

Construction

The concrete slab was poured in the spring. Our boys learned about mixing, pouring, and finishing cement. The 5 gallon bucket in the middle of the slab is where the smoke will enter the smokehouse. The slab is what is called a “floating” slab. There is no frost footings below the slab, it is simply framed to have a 10 x 10 inch “curb” around the outside of the slab and the rest of the slab is 4 inches thick. There is also reinforcing rebar in the curb and criss-crossed across the slab. I don’t think it is going anywhere, and after one winter of freezing and thawing, there are no signs of cracking or shifting.

Jesse’s uncle, a mason by profession, came over to help in building the smokehouse. His skills amazed us as he tossed just the right amount of the mud in just the right place.

Jesse did a great job supervising….

Jesse designed the smokehouse to have glass block windows to allow in natural light. Laying the glass block was the most time-consuming part of the block laying process and the expertise of Jesse’s uncle was definitely necessary to get the glass blocks set just right. Our son worked on smoothing the joints between the blocks.

After the blocks were cured, Jesse and our son went to work building roof trusses, sheeting the roof, and laying shingles. Jesse decided to build the trusses so that the rafters could be used for hanging meat, so they are about 6 ft. high.

There are vents covered with window screen in the peak at each end of the smokehouse for draft. Jesse had built elaborate hinged doors for adjusting the draft level if needed. However, the correct draft position turned out to be full open.

Firebox

The firebox for a cold smokehouse is located away from the smokehouse to allow the smoke to cool before entering the smokehouse. The smoke from our firebox increases the temperature in the smokehouse a mere 5 to 10 deg F. This allows Jesse to safely cold smoke on days as warm as 60 degrees, but he prefers to have the outside temperature around 30 – 40 degrees.

The tricky part for the firebox is that in order to have adequate draft for the smoke to enter the smokehouse, the firebox should be located about 10 – 12 inches below the smokehouse floor and 8 – 10 feet from the center hole in the smokehouse. So the only logical way to build this operation is to locate the smokehouse on a hill or slope with enough fall to allow access to the firebox.

The firebox can be made from concrete and firebrick with a sliding steel door, but Jesse chose to use an actual home fireplace insert that someone had discarded into a road ditch. With the air intake vent controls on the fireplace he figured that he could control the fire for smoking to just the right levels (and it works perfect). He dug a hole into the side of the hill for the fireplace, and left enough room for about 2 – 3 inches of sewer rock around the fireplace to assist in water drainage around the fireplace. With the heavy gauge steel, the fireplace insert should last longer than our lifetime before it rusts out (it weighed about 5oo lbs. and had to be moved into place by a tractor).

Jesse used 8 inch chimney pipe to connect the firebox to the 5 gallon bucket in the floor of the smokehouse. Obviously you want to install the pipe before you pour the concrete floor. The reason he chose the 8 inch metal chimney pipe was that the firebox had an 8 inch exit, and he needed something that would withstand the heat near the firebox. He says that he would NOT recommend using PVC or other plastic pipe as it may melt or out-gas if heated.

And here is our lovely little smokehouse in action…..

Maybe a bit over-sized for your casual home smoking, but it works GREAT!

–Lynell

Good smokehouse! And beautiful it looks!

Thank you.

Amazing…I’m a DIYer from way back but not sure I would attempt without those four guys to help!

I think it is great. One question for you modern day farmer. My husband grew up on a farm, I am a city person. However, I would like to buy a small farm; I always wanted to do that. Anyway, my question is. Can one build a smoke house and due away with the modern day freezer or fridg. I would like to be able to go to the smoke and pick out dinner. Is that possible.

In our modern times we add wood smoke for the flavor. There are many serious dangers in food safety if you don’t refrigerate or freeze meats, especially sausages as they are good breeding grounds for bacteria. Curing meats with nitrates and nitrites are a very important step in food preservation and the smoking is an additional step that is also an aid in the curing. I would recommend that you thoroughly research curing and smoking before you consider to do away with refrigeration and freezing, which I personally would not attempt.

Will you particular design work for hot smoking as well? I love the design. Are the eves closed completly ? How did you attach the roof onto the block without leaving gaps where the trusses extend out beyond the block. (normally on a house this is where the soffit goes.) Thanks

Unfortunately this design doesn’t work for hot smoking. I have a separate barrel smoker for hot smoking / barbecue.

The eves are closed off by building a soffit with 2×4 cross members and plywood. Don’t worry about having the eves airtight as having the building breathe a little gets rid of excess humidity and moisture. Having small gaps along the sill plate also encourages better smoke circulation along the walls. I will ask my wife to post some new pics when she gets a chance.

–Jesse

It is a good size. As you can trade meat for smoking services. Thank you for sharing!

How would I make this a hot smoke house? I would like to build one like this but not for cold. Thank you for your time.

Hi Thom,

This type of design does not lend itself easily to hot smoking, but if you are interested to pursue hot smoking here are a few of my thoughts. First is the location of the heat source. The current design has the heat source located 6-8 feet away from the smoke house and the smoke travels through the chimney pipe in the ground to cool the smoke. Therefore you would need to adjust the design to have the fire box directly next to the smoke house and use an insulated chimney to limit the cooling. Second issue that needs to be addressed is the heat loss through the roof. The current design gives good ventilation and easy transfer of heat through the roof to the outside. To retain the heat longer to reach higher cooking temperatures I would recommend using a 2 inch insulation board on the inside of the roof/ceiling. To avoid outgassing of insulation materials as they are heated, I would look for the type of insulation board that has a tin foil layer on one side.

If you decide to modify my design for hot smoking, I would love to see pictures of your plans and final results.

Best Regards,

Jesse

Um, I think it is actually much easier than you think to hot smoke in this thing – I have a Mennonite friend who has an almost identical building; the only thing he does differently is to put a pan of moist hickory shavings on the floor directly below the meat and fire it up.

hi, great build. doing research on this and never really made my own smoke house. in terms of maintenance, how hard is it and how often do you have to clean the inside of the smokehouse? just worried bout the maintenance and health inspectors. thanks!

Great design and building information. Thank you. You had the option of building your firebox below the smokehouse by use of the land’s natural slope. I live in Oklahoma where the entire farm is as flat as your dinner table. Do you have any suggestions on how I could use your plans since I would not be able to place the firebox below the floor level of the smokehouse? Thank you for your suggestions and information.

Hi Russ – glad you got some value from the blog posts on the smokehouse. You are absolutely right that I was able to take advantage of the natural terrain. Obviously digging a pit to bury your firebox and have good access to it would require a substantial size hole. The only other viable option that I can think of is to elevate your smokehouse with a couple of courses of blocks, and then replace the concrete floor with a wooden one. You won’t get the same cooling effect from direct contact of the chimney pipe with the ground, but you would get some cooling nonetheless. Maybe even making the chimney pipe longer could provide more cooling. The net effect of losing the cooling from the ground is that you would have higher heat rise in the smokehouse, which means you would have to smoke when it’s colder outside. To be on the safe side with cold smoking you should always stay below 60 degrees inside your smokehouse. With my smokehouse arrangement I get only a 10 degrees temp rise when I fire up the smokebox. You would have to experiment with an alternative design and see what your temp rise would be.

Hope I have provided at least some sparks for ideas on how you could adapt my design for your environment.

Good Luck

Jesse

Thank you for the helpful ideas.

Since it is best to have temperatures at or below 60 degrees that will make using the smokehouse to the months of November thru March in the Oklahoma climate.

What is the difference (advantage Vs. disadvantage) of heat smoking Vs. cold smoking? Does one preserve better or longer? My interest in making a smokehouse is for preservation without the taste of freezerburn.

Thank you for your time and information.

Sincerely,

Russ Burger

Tonkawa, Oklahoma

Russ, I haven’t done much research into meat preservation, but I believe that most preservation techniques use primarily curing (salting and nitrites) and drying processes. Smoking can be part of a drying process but is most commonly used for flavoring the meat. I can give you some tips on the difference between hot smoking and cold smoking. Hot smoking is also commonly referred to as barbequeing. During the hot smoking process you are also cooking the meat at the same time. This is a great process for brisket, fish, chicken, and other non-cured meats. Cold smoking does not cook the meat, it only imparts the smoke flavor. Cold smoking works well for sausages, chicken, ribs, pork chops, cheese, and nuts. For example you will find on the blog some information on sausage making. Our family butchers an entire hog (or two) which we smoke and then put into the freezer and cook later. There are also some good books you can find on Amazon. Good luck!

Jesse

Thank you. You have been a great help.

You can either elevate your smoke house or dig your firebox deeper.

A 90 degree coming our of the top of your firebox to your smoke house and 90 degree turn up into your smoke house. Make sure if your firebox is metal and is buried you put drainage under it so it won’t rust as fast.

What a lovely smokehouse. I’m so impressed. However, I question why the window? In time it will get smoked over but I was raised the meat shouldn’t be exposed to light when it’s hanging in the smokehouse.

Thanks for stopping by our blog. There are actually 2 windows, one on each opposing side. There is no electricity in the smokehouse, so no artificial light, and hence my desire for adding a window for improved visibility inside. I actually have to give credit to the window idea to Uncle Greg 🙂 Have you ever tried to check on your meats in a dark smokehouse filled with smoke? Not easy. I have to admit that I’ve never seen a window in any old time smokehouses either, but I’m assuming that was more of a practical matter of cost and material availability. You can probably tell from the photos on our blog that we have a “gentleman’s farm” and not a real working farm, and don’t the windows make the smokehouse even more attractive?!?! The glass blocks that I used are very sturdy and surprisingly enough they don’t seem to be getting smoked-over even after 3 yrs of use. I will probably clean them off someday, which should also be pretty easy to do with an oven cleaner similar to what I use on the glass doors of the wood fireplace in our house. As far as sunlight exposure to meat, here are my thoughts. In general I would agree that direct sunlight on uncooked meats is probably not desireable as it will tend to heat the surface of the meat and that would encourage bacteria growth. However, my smokehouse is for cold-smoking meats only and that means that I am smoking meats only when the outside temperature is below 50 deg F., which ensures that bacteria growth is not likely. In addition, with the thick glass blocks, smoke filled house, and trees overhead, at best the windows would allow in only heavily filtered light and never a chance for direct sunlight. If product quality is the truest testiment to the addition of the window, I can tell you that our cold smoked meats are some of the best that I have ever tasted!

very cool smoke house your guys I live in southern va were researching getting a slaughter house butcher shop going after all the red tape is worked through but smoking meat is a specialty feature we would love to offer in the butcher shop hams ribs etc. I thought of using two fire boxes in my design one close for hot smoke one away with underground pipe for cold smoke thanks for insperation

Good luck Ken. Would love to see pictures when you are finished!

Jesse

great thought may try this. never tried cold smoke I only have a small hot smoker,I would like to put it inside the building so I can smoke all year.I central Canadian prairies now it is -30 degrees and that doen`t count the wind chill

Bob

In a word…Fantastic.My son posted your Smokehouse build on my page..and a few more,but this is definitely the one we are going to build within the next few month’s.Thank you for taking the time and sharing. Jim.

Here in the Panhandle of Florida, how do you keep roaches ,spider’s, rat’s and other unwanted guest from getting in the smokehouse ?

Hi Bill,

Sorry it took me so long to reply, but just noticed your comment. We definitely get spiders and other insects in the smokehouse, but roaches and rats are not an issue around here. Our winters pretty much kill off any living thing. Also, anything we smoke either hangs from the rafters or is on metal racks, so spiders and such are of no big concern.

-Lynell

Fantastic! It is my dream to have a smoke house like this! We have a small homestead, not a working farm. ( although I work pretty hard here.) We are working towards self sufficiency. We currently breed/raise American Guinea Hogs for sale and our own meat. Smoking our own meat would be a blessing. Now I need to get my husband motivated to build one just like yours, lovely and efficient!

Pingback: 12 Smokehouse Plans For Better Flavoring, Cooking and Preserving Food (meat) | The Self-Sufficient Living

Pingback: 12 Smokehouse Plans For Better Flavoring, Cooking and Preserving Food | The Self-Sufficient Living

Pingback: How to Build a Smoker or Smokehouse

Pingback: Build a smokehouse from cement blocks | DIY projects for everyone!

Can this be used for hot smoking also?

Hi Justin, No, this is only for cold-smoking. Because the wood box is located away from the smokehouse, it does not get hot enough inside to hot smoke. We have a barrel smoker for that use. Thanks for stopping by! -Lynell

If you put a fire box inside as well you can do either hot or cold then you can choose

Hi Justin and Bob,

We also have a barrel hot-smoker, so we only use this for cold-smoking. -Lynell

Outstanding Smokehouse , Design on down . Perfect for what I am looking for. I have a

Question if I may – I noticed on the design

drawing calling for “Burnished Block”. Love the

Look – I see specialty companies offer it (No Pricing)

, and I do not see it online at the common big box

stores – Where and rough costs for blocks

if I may? Trying to budget this project.

Warm regards,

Slip

Hi Slip,

We built the smokehouse in 2009 and at that time, the cost of the blocks was around $550.00. Ours came from a company called Amcon Block & Precast, Inc. I hope that helps!

-Lynell

My husband and I are in the process of building a simular smoke house, I love the glass block idea. I will definitely add that to mine. We are poring the slab for the fire box today, I am lining the inside of the smoke house and fire box with fire bricks so I can later add the heat later. This will allow use to use the same house for both hot and cold smoke. HOPEFULLY LOL

Pingback: 14 Simple Smokehouse Plans for Cooking Food - Lemon Slide

Pingback: 25 Smokehouse Plans For Better Flavoring, Cooking and Preserving Food | The Self-Sufficient Living

Pingback: 25 Smokehouse Plans For Better Flavoring, Cooking and Preserving Food – The Self-Sufficient Living

I think it is great. Outstanding Smokehouse. We also have a barrel hot-smoker, I’m so impressed. However, I question why the window? I bought my all smoker and equipment from here: https://ozarmour.co/en-eu/collections/all

Pingback: 20 Free DIY Smokehouse Plans (How to Build a Smokehouse) - DIY Cozy Home